Prosthetic limbs have come a long way, evolving from simple wooden structures to advanced bionic devices that respond to muscle signals. While traditional prosthetics provide essential functionality, bionic limbs are pushing the boundaries of what is possible, offering users greater control, adaptability, and even sensory feedback. But one technological breakthrough has changed the way both types of prosthetics are designed and produced—3D printing.

3D printing has revolutionized prosthetic manufacturing by making the process faster, more affordable, and highly customizable. Unlike conventional methods, which rely on labor-intensive molding and machining, 3D printing allows for the creation of prosthetic limbs with precision and efficiency. This has made prosthetics more accessible to individuals worldwide, particularly in regions where cost and availability have been significant barriers.

From enhancing the design of traditional prosthetics to enabling the development of more advanced bionic limbs, 3D printing is transforming the future of prosthetic technology. In this article, we explore how 3D printing is shaping the evolution of both traditional and bionic prosthetics, the benefits it offers users, and what the future holds for this exciting innovation.

How 3D Printing is Changing Traditional Prosthetics

Traditional prosthetics have always played a crucial role in restoring mobility and independence to individuals with limb loss. They provide structural support and basic functionality, helping users perform daily activities with greater ease.

However, the process of making traditional prosthetics has historically been slow and expensive. This is where 3D printing is making a significant impact.

Faster and More Affordable Production

One of the biggest challenges with traditional prosthetics has been the cost.

The materials and labor required to create custom prosthetic limbs using conventional methods are expensive, making them inaccessible to many individuals, especially in low-income regions. With 3D printing, this cost is dramatically reduced.

3D printing allows for the rapid production of prosthetic limbs using lightweight, yet durable materials.

Instead of waiting weeks or months for a prosthetic to be manufactured, users can receive a custom-fit limb in a matter of days. This is particularly beneficial for children, who frequently outgrow their prosthetics and require replacements more often.

At Robobionics, we have seen firsthand how 3D printing has made prosthetics more affordable and accessible, helping individuals regain independence without financial strain.

Customization for a Better Fit

No two individuals are the same, and neither are their prosthetic needs. Traditional manufacturing methods often result in prosthetics that require multiple adjustments before they fit comfortably.

3D printing eliminates this issue by allowing for highly customized designs that match the user’s exact measurements.

With digital scanning technology, a precise model of a user’s residual limb can be created, ensuring a prosthetic that fits perfectly. This reduces discomfort, improves functionality, and enhances the overall experience for the user.

Customization also extends to design aesthetics—3D printing allows individuals to choose colors, patterns, and even unique shapes that reflect their personality and style.

Lighter and More Comfortable Materials

Traditional prosthetics have often been made from heavy materials, which can cause strain on the user’s body, leading to discomfort and fatigue.

3D printing offers the ability to create prosthetics using lightweight yet strong materials such as carbon fiber composites and advanced polymers.

These materials reduce the overall weight of the prosthetic, making it easier to wear for extended periods. Additionally, 3D-printed designs can incorporate better weight distribution, making movement more natural and reducing pressure points that often cause irritation.

How 3D Printing is Advancing Bionic Prosthetics

While 3D printing has significantly improved traditional prosthetics, its impact on bionic limbs is even more profound. Bionic prosthetics are designed to replicate natural movement, respond to muscle signals, and, in some cases, provide sensory feedback.

These devices are highly complex, requiring intricate engineering and precision manufacturing. 3D printing has made it possible to develop bionic limbs that are more affordable, customizable, and efficient, bringing futuristic prosthetic technology within reach of more people.

Rapid Prototyping for Faster Innovation

One of the most exciting ways 3D printing is influencing bionic prosthetics is through rapid prototyping. Traditionally, designing a bionic limb involved multiple iterations, each requiring extensive manufacturing time and high costs.

Every small adjustment meant building a new prototype from scratch, delaying the process of getting a functional prosthetic to users.

With 3D printing, engineers and designers can quickly test new ideas, refine designs, and create prototypes within hours instead of weeks.

This accelerates the development of advanced bionic limbs, allowing for continuous improvements in function, comfort, and durability. Researchers can experiment with different materials, shapes, and configurations without the high cost of traditional manufacturing methods.

At Robobionics, we use 3D printing to refine our prosthetic designs, ensuring that each new model offers better performance and a more natural feel for users.

More Affordable Bionic Prosthetics

Bionic limbs are typically expensive due to the advanced electronics, sensors, and materials used in their construction. 3D printing helps reduce these costs by enabling the production of complex components at a fraction of the price of traditional manufacturing.

For example, the structural framework of a bionic hand, which was once costly to machine from metal or molded plastic, can now be printed in lightweight, durable materials.

This significantly lowers the production cost while maintaining strength and functionality. The result is a more affordable bionic prosthetic that is accessible to a wider audience.

Customization for Better Performance

Bionic prosthetics need to work seamlessly with the user’s body, adapting to their specific movements and muscle signals. 3D printing allows for greater personalization, ensuring that each prosthetic is tailored to the individual’s needs.

With digital modeling and scanning technology, a prosthetic limb can be designed to match the user’s residual limb precisely. This improves the connection between the limb and the prosthetic, enhancing responsiveness and making movement more intuitive.

Customization also extends to functionality—3D-printed bionic limbs can be designed with interchangeable parts, allowing users to switch between different grip types, mobility settings, or attachments based on their daily activities.

Bridging the Gap Between Traditional and Bionic Prosthetics with 3D Printing

While traditional and bionic prosthetics serve different needs, 3D printing is helping to bridge the gap between them. The same technology that makes traditional prosthetics more affordable and accessible is also making bionic limbs smarter, lighter, and more adaptable.

By integrating 3D printing into both types of prosthetics, manufacturers can provide users with the best of both worlds—durability, functionality, and advanced technology at a lower cost.

Hybrid Prosthetics: Combining Mechanical and Bionic Features

One of the most exciting developments in prosthetic design is the rise of hybrid prosthetics—devices that combine the simplicity and durability of traditional limbs with the advanced functionality of bionic technology.

3D printing makes it possible to integrate mechanical and electronic components seamlessly, allowing for prosthetic limbs that offer both strength and flexibility.

For example, a hybrid prosthetic hand may use a 3D-printed frame for structural support while incorporating lightweight electronic actuators for better finger movement.

This allows users to benefit from some aspects of bionic control without the high costs or maintenance challenges of a fully robotic limb. The ability to 3D print modular components means that users can upgrade specific features over time rather than replacing the entire limb.

Adaptive Prosthetics for Children and Growing Users

One of the biggest challenges in prosthetic care is providing children with functional limbs as they grow. Traditional prosthetics are expensive and difficult to adjust, meaning that children often outgrow their devices before they can get a replacement.

3D printing solves this problem by allowing for scalable, adjustable prosthetics that can be easily modified as a child grows.

Bionic prosthetics for children have also become more viable thanks to 3D printing. Previously, advanced prosthetic technology was largely unavailable to younger users due to high costs and difficulty in scaling the design for smaller limbs.

With 3D printing, pediatric prosthetics can now be customized in a way that is both affordable and functional, ensuring that children have access to the same innovations as adults.

At Robobionics, we recognize the importance of adaptability in prosthetic design. Our use of 3D printing allows us to create prosthetics that grow with users, reducing the financial and logistical burden of frequent replacements.

Sustainability and Environmental Benefits

3D printing is not just revolutionizing prosthetic design—it is also making the entire industry more sustainable. Traditional prosthetic manufacturing generates a significant amount of material waste due to cutting, molding, and machining processes.

In contrast, 3D printing is an additive process, meaning that material is only used where needed, reducing waste significantly.

Additionally, many modern 3D printing materials are recyclable or biodegradable, making prosthetic production more eco-friendly.

As the world moves toward greener solutions, the prosthetics industry is following suit, with 3D printing leading the way in sustainable manufacturing.

The Future of 3D Printing in Prosthetics

3D printing has already transformed the way prosthetic limbs are designed and manufactured, but its full potential is only just beginning to be realized.

As printing technology continues to advance, prosthetics will become even more functional, accessible, and personalized. From ultra-lightweight materials to fully integrated smart prosthetics, the future of 3D-printed prosthetics holds exciting possibilities.

Integration with Smart Technology

One of the most promising directions for 3D-printed prosthetics is the integration of smart technology. Researchers are already experimenting with prosthetics that feature built-in sensors, artificial intelligence, and even internet connectivity.

With 3D printing, these smart prosthetics can be produced more efficiently, reducing the cost and making them more widely available.

In the future, prosthetics could automatically adjust to the user’s activity level, detect muscle fatigue, or even send real-time data to healthcare professionals for remote monitoring.

A 3D-printed prosthetic leg, for example, could use AI to adapt its movements based on terrain changes, allowing for a more natural and effortless walking experience. These innovations will make prosthetic limbs more intuitive, improving both comfort and functionality.

Advancements in Biocompatible Materials

Currently, most 3D-printed prosthetics use plastics, carbon fiber, or lightweight metals. However, new research is focusing on biocompatible materials that can interact more naturally with the human body.

These materials could help reduce skin irritation, improve long-term comfort, and even encourage better integration between the prosthetic and the residual limb.

Scientists are also exploring 3D-printed bioengineered tissues that could one day be used in prosthetic sockets. These materials would conform more precisely to the user’s body, eliminating discomfort and making prosthetics feel more like a natural extension of the body.

Self-Healing and Adaptive Prosthetics

One of the biggest challenges with prosthetics is wear and tear. Over time, mechanical parts degrade, and materials weaken.

Future 3D-printed prosthetics may feature self-healing materials that can repair minor cracks or damage on their own, extending the lifespan of the device.

Adaptive prosthetics that change shape in response to the user’s needs are also in development.

These prosthetics would be able to expand, contract, or adjust their stiffness depending on the activity—providing more flexibility for users who switch between different tasks throughout the day.

Making Prosthetics More Widely Available

Perhaps the most significant impact of 3D printing in prosthetics is its ability to make high-quality artificial limbs available to more people. In developing countries, access to prosthetic care has traditionally been limited due to high costs and a lack of specialized clinics.

With 3D printing, prosthetic limbs can be produced locally at a fraction of the cost, bringing life-changing mobility solutions to those who need them most.

Organizations around the world are now using 3D printing to create prosthetic limbs for individuals in underserved communities. As the technology continues to improve, even the most advanced bionic prosthetics may become accessible on a global scale.

The Role of 3D Printing in Emergency and Disaster Response Prosthetics

One of the lesser-known but highly impactful applications of 3D printing in prosthetics is its role in emergency and disaster response.

Natural disasters, war zones, and industrial accidents can lead to a sudden increase in amputations, leaving many individuals in urgent need of prosthetic solutions.

Traditional prosthetic manufacturing is often too slow and expensive to meet these immediate demands, but 3D printing offers a way to provide quick, cost-effective solutions in crisis situations.

Rapid Deployment of Prosthetics in Crisis Zones

After earthquakes, war conflicts, or major accidents, many survivors require emergency medical care, including amputations.

In these situations, access to prosthetics can be life-changing, allowing individuals to regain mobility and independence quickly. However, conventional prosthetic manufacturing requires weeks or months, making it nearly impossible to provide immediate support.

3D printing allows for on-site prosthetic production in disaster zones. Mobile 3D printing labs can be deployed to affected areas, creating customized prosthetic limbs in a matter of hours.

With the ability to scan a patient’s residual limb and print a prosthetic tailored to their measurements, individuals can receive functional prosthetics almost immediately.

This not only helps restore mobility but also prevents long-term complications caused by prolonged immobility.

Low-Cost Solutions for War and Refugee Populations

In war-torn regions, prosthetic care is often limited due to destroyed medical infrastructure and financial barriers. Many individuals, including civilians and soldiers, suffer amputations but have no access to proper prosthetic care.

3D printing has emerged as a powerful tool in these areas, providing affordable and scalable prosthetic solutions.

Organizations and humanitarian groups are now using 3D printing hubs in refugee camps and war zones to manufacture prosthetics on demand.

Instead of relying on expensive international shipments of traditional prosthetics, these organizations can print custom prosthetic limbs locally using affordable materials. This ensures that individuals in conflict zones receive the care they need without long delays or high costs.

Temporary and Transitional Prosthetics for Rehabilitation

For individuals recovering from trauma, the first prosthetic they receive is often a temporary or transitional limb used during the healing process.

These initial prosthetics help patients adjust to limb loss before being fitted with a long-term prosthetic solution. However, traditional temporary prosthetics can be expensive, making them inaccessible for many patients.

3D printing provides an affordable and scalable alternative for temporary prosthetics. These prosthetics can be quickly customized to match a patient’s needs, giving them mobility while they wait for a permanent solution.

Since they can be printed with cost-effective materials, they offer a practical way to bridge the gap between amputation and long-term prosthetic use.

The Future of 3D Printing in Humanitarian Prosthetics

As 3D printing technology continues to improve, its role in humanitarian aid will only expand.

Future advancements in biodegradable materials, remote-controlled printing, and modular prosthetic designs will make it even easier to provide life-changing prosthetic solutions in crisis situations.

Governments and aid organizations are increasingly recognizing the potential of 3D printing in emergency medical response, paving the way for a future where no amputee is left without access to a functional limb.

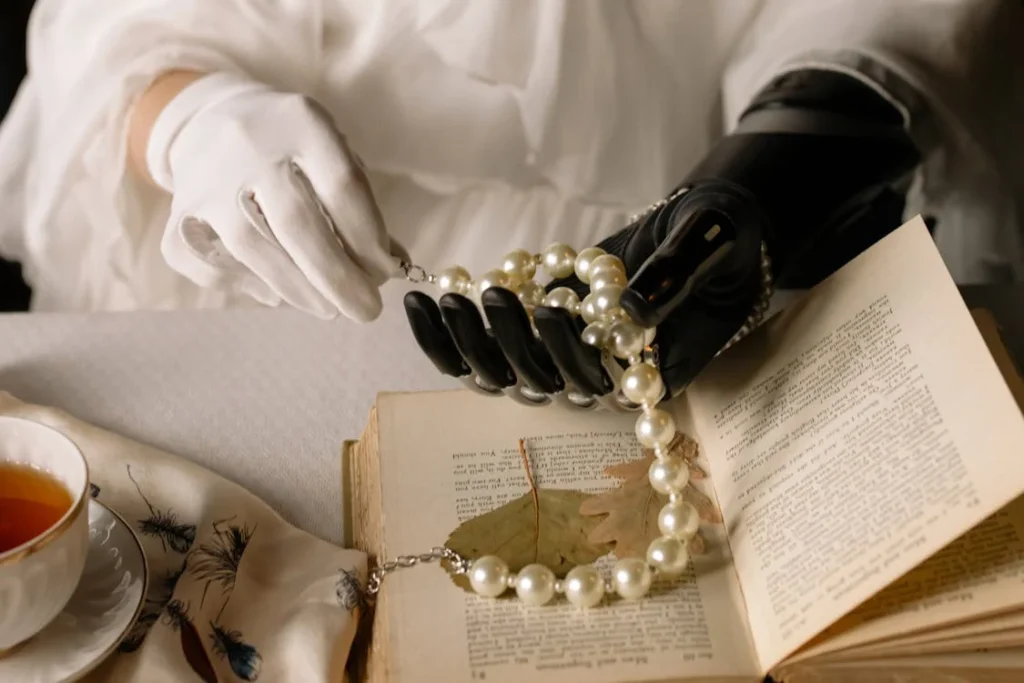

The Role of 3D Printing in Enhancing Prosthetic Aesthetics and Personalization

Beyond functionality, 3D printing is transforming the way prosthetic limbs look and feel. While traditional prosthetics were often designed with a clinical and uniform appearance, modern prosthetic users are demanding more customization, aesthetics, and self-expression.

3D printing allows for an unprecedented level of artistic and personal customization, making prosthetic limbs not just medical devices, but extensions of personal identity.

Custom-Designed Prosthetics for Self-Expression

In the past, prosthetic limbs were primarily focused on function, with little attention given to their appearance. Many users felt self-conscious about wearing prosthetics that looked artificial or overly mechanical.

3D printing has changed this by enabling prosthetic limbs to be designed with intricate patterns, unique textures, and customized shapes that match the user’s preferences.

Some individuals choose prosthetic limbs with bold colors, futuristic designs, or even nature-inspired aesthetics. Others prefer sleek, minimalist styles that blend naturally with their body.

With 3D printing, prosthetic users are no longer limited to standard models—they can create designs that reflect their personality, interests, and sense of style.

Creating Hyper-Realistic Prosthetics

For those who want their prosthetic to look as natural as possible, 3D printing has also enabled the creation of hyper-realistic prosthetic limbs.

Advanced 3D scanning and printing technologies allow for the production of prosthetic covers that perfectly match the user’s skin tone, texture, and even features like freckles or veins.

These custom prosthetic covers help users feel more comfortable in social situations, as they provide a natural-looking limb that blends seamlessly with their body.

Unlike traditional silicone prosthetics, which were expensive and took weeks to manufacture, 3D-printed realistic prosthetic covers can be created quickly and at a lower cost.

Adaptive Fashion and Prosthetic Art

A growing movement in the prosthetics industry is prosthetic fashion, where users turn their limbs into works of art.

Many designers and artists are collaborating with prosthetic manufacturers to create wearable sculptures, engraved prosthetic covers, and interchangeable limb designs that allow users to switch their prosthetic’s appearance based on their mood or occasion.

For example, some prosthetic users have designs inspired by superheroes, while others prefer prosthetic covers featuring cultural artwork or geometric patterns.

With 3D printing, these designs can be easily changed, giving users the ability to express themselves in a way that was never possible before.

Aesthetic and Functional Customization for Special Occasions

3D printing has also made it possible for users to customize prosthetics for special events. Some individuals opt for elegant designs for weddings, formal events, or celebrations, while others commission custom prosthetics for performances or themed occasions.

With 3D printing, a prosthetic user can have multiple interchangeable covers to suit different settings, adding a new layer of self-expression to their experience.

Breaking the Stigma Around Prosthetics

One of the most powerful impacts of 3D printing in prosthetic aesthetics is its ability to change public perception. In the past, prosthetic limbs were often associated with disability and medical necessity.

Today, with personalized and beautifully designed prosthetics, they are becoming symbols of empowerment, resilience, and individuality.

By turning prosthetic limbs into art, fashion, and self-expression, 3D printing is helping to reduce stigma and encourage society to see prosthetic users in a new light—not as individuals with limitations, but as people with unique stories, creativity, and confidence.

Conclusion

3D printing has revolutionized the world of prosthetics, making both traditional and bionic limbs more accessible, functional, and personalized than ever before. From reducing costs and improving fit to enabling artistic self-expression, this technology is transforming the way prosthetic limbs are designed and used. Whether it is creating affordable prosthetics for disaster relief, developing advanced bionic limbs with AI integration, or allowing users to personalize their prosthetics for fashion and aesthetics, 3D printing is driving innovation in every aspect of prosthetic development.

The future of prosthetic technology is bright, with ongoing advancements in smart materials, neural integration, and adaptive designs promising even more natural and intuitive solutions. As 3D printing continues to evolve, it will further break down barriers, ensuring that high-quality prosthetic limbs are available to more people around the world.

At Robobionics, we are proud to be at the forefront of these innovations, providing advanced prosthetic solutions tailored to individual needs. If you are exploring prosthetic options, contact us today for a free consultation and discover how 3D printing is shaping the future of mobility and independence.